There are no products listed under this category.

Industries Served

Ball Bearing Rebuilders Cleaning Guide

NuGenTec has your solution for rebuilding ball bearing assemblies for any process, including:

- Vapor Degreasing

- High-Pressure Spray Tank Cleaning/Degreasing

- Ultrasonic Tank Cleaning/Degreasing

For Vapor Degreasing Equipment:

TCE and nPB have been classically used, however, due to the hazards associated with these chemicals they are being phased out. NuGenTec has better and safer alternatives. FluoSolv Ten-X has an industry proven track record as perhaps the best solvent for vapor degreasing of all soils encountered by the ball bearing remanufacturing/rebuilding marketplace. FluoSolv Ten-X is non-flammable, non-toxic and non-carcinogenic. FluoSolv Ten-X is the industries best choice for vapor degreasing applications.

For high-pressure spray washers:

AquaKlean STC-HT should be your product of choice for industrial spray washing systems. Water-based, effective on all soils ball bearing rebuilders face such as greases, oils, hydrocarbons, dirt, particulate matter and stubborn soil combinations of greases, paraffins, and particulates. Use AquaKlean STC-HT at 1-5% by volume with water. For those who need a non-corrosive choice for spray cleaning, we recommend AquaKlean SUS.

For ultrasonic cleaning systems/tanks:

CitraKlean Clear should be your product of choice for ultrasonic cleaning systems. Water-based, effective on all soils ball bearing rebuilders face like greases, oils, hydrocarbons, dirt, particulate matter and stubborn soil combinations of greases, paraffins, and particulates. Use CitraKlean Clear at 5-10% by volume with water in ultrasonic tank systems.

Products to choose from:

- Vapor Degreasing - FluoSolv Ten-X

- High-Pressure Spray Washing - AquaKlean STC-HT

- Ultrasonic Tank Cleaning - CitraKlean Clear

- Removal of Silicone Oils - NuSolv SOR Series: SOR, SOR-C, SOR-A

Features

- To the best of our knowledge, this product is California Prop 65 compliant.

- Ball Bearing Rebuilders Cleaning Guide

| Physical Properties | CitraKlean Clear |

| Use concentration Use concentration (ultrasonics) |

1:64 to Full Strength 1:20 to 1:10 |

| Density | 1.02 g/ml (8.5 lbs/gal) |

| Operating Temps | Ambient to 60°C (140°F) |

| Soluble in water | Complete |

| pH, Concentrate | 10.5 |

| Corrosive | No |

| Biodegradable | Yes |

| Physical Properties | AquaKlean STC-HT |

| Use concentration (spray) Use concentration (ultrasonics) |

1-5% by volume 2-10% by volume |

| Density | 1.33 g/ml (11.1 lbs/gal) |

| Operating Temps | Ambient to 88°C (190°F) |

| pH @ 5% | 13.2 |

| Flash Point | None |

| VOC (concentrate) | 0 g/l |

| Biodegradable | Yes |

Safety

Please make sure you have read and understand the product label and SDS before using this product. Avoid breathing vapors, spray or mists. Use only with adequate ventilation. Wash thoroughly after handling. Observe label precautions.

NuGenTec offers inorganic chemicals to be utilized in product manufacturing and to companies wishing to package and resell our bulk inorganic chemicals.

Features

To the best of our knowledge, this product is California Prop 65 compliant.

A great short course video Biochemistry: The Amino Acids, Peptides, and Proteins. Courtesy of MIT / CHEMISTRY

By Donald R. Sadoway

Watch it on Academic Earth

COURSE DESCRIPTION

This course explores the basic principles of chemistry and their application to engineering systems. It deals with the relationship between electronic structure, chemical bonding, and atomic order. It also investigates the characterization of atomic arrangements in crystalline and amorphous solids: metals, ceramics, semiconductors, and polymers (including proteins). Topics covered include organic chemistry, solution chemistry, acid-base equilibria, electrochemistry, biochemistry, chemical kinetics, diffusion, and phase diagrams. Examples are drawn from industrial practice (including the environmental impact of chemical processes), from energy generation and storage, e.g., batteries and fuel cells, and from emerging technologies, e.g., photonic and biomedical devices.

Call us at 888-996-8436 x5 or Email us at pharma@nugentec.com

Boeing's manufacturing and production processes rely on rigorous specifications to ensure the highest quality and performance standards. Among these, BAC 5408 and BAC 5402 are critical for maintaining the integrity of both nonmetallic and metallic materials used in aerospace applications.

BAC 5408: Nonmetallic Material Control Specification

BAC 5408 sets the requirements for controlling nonmetallic materials used in Boeing aircraft and aerospace products. This includes adhesives, sealants, coatings, and other nonmetallic substances crucial to the construction and maintenance of aerospace vehicles.

Key Elements:

- Material Qualification: Ensures nonmetallic materials meet stringent Boeing standards before approval.

- Process Control: Provides guidelines for handling, storage, and application to maintain material integrity and performance.

- Testing Requirements: Specifies tests to verify properties and suitability for aerospace use.

BAC 5402: Surface Preparation and Pretreatment for Metallic Materials

BAC 5402 outlines procedures for the preparation and pretreatment of metallic surfaces, ensuring proper adhesion of coatings, adhesives, and sealants. This is essential for the durability and reliability of aerospace components.

Key Elements:

- Surface Cleaning: Details methods for removing contaminants from metallic surfaces to ensure optimal adhesion.

- Pretreatment Processes: Describes chemical and mechanical processes to enhance bonding properties.

- Inspection Requirements: Sets criteria for inspecting treated surfaces to meet Boeing’s cleanliness and preparation standards.

By adhering to these specifications, Boeing ensures that both nonmetallic and metallic materials used in their products are of the highest quality, guaranteeing safety and efficiency in aerospace operations. These standards are a testament to Boeing's commitment to excellence and reliability in the aerospace industry.

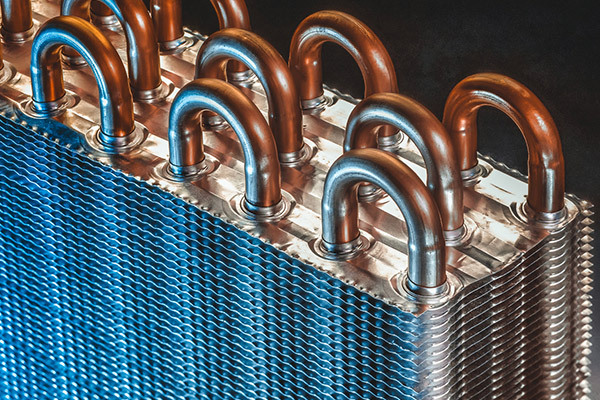

NuGenTec Announces Exclusive Partnership with BVV

The strategic alliance makes BVV the exclusive distributors of NuGenTec’s high-performance heat transfer fluid NuTherm™ PF-50.

NuGeneration Technologies (NuGenTec) and BVV recently entered into a strategic alliance that gives BVV exclusive distributorship of NuGenTec’s NuTherm PF-50 high-performance heat transfer fluid. This partnership lets BVV provide a safer and more effective product for their customers while opening up new markets for NuGenTec’s eco-friendly chemical products.

About BVV

BVV designs and engineers high quality, highly efficient, and cost-effective vacuum chambers, extractors, and material processing equipment. They provide innovative products across numerous extensive product categories to meet the needs of a variety of industries and applications.

To learn more about BVV and their reliable and efficient products, visit www.shopbvv.com.

Below is a list of products distributed by BVVs, particularly chosen for industries such as cannabis, hemp, and medical marijuana. These products are high purity, best in class, the most environmentally conscious in their respective classes, economical, and readily available.

Features

- To the best of our knowledge, this product is California Prop 65 compliant.

- Composed of legal cultivators and producers of cannabis and its industrial derivative, hemp

- Canada is set to become the first country to legalize private sales of recreational marijuana with Bill C-45 in 2018 Cannabis in Canada.

- Medical marijuana industries

- ASTM D37 Compliant

- Chemicals available in Pharmaceutical and Biopharmaceutical (ACS) grades

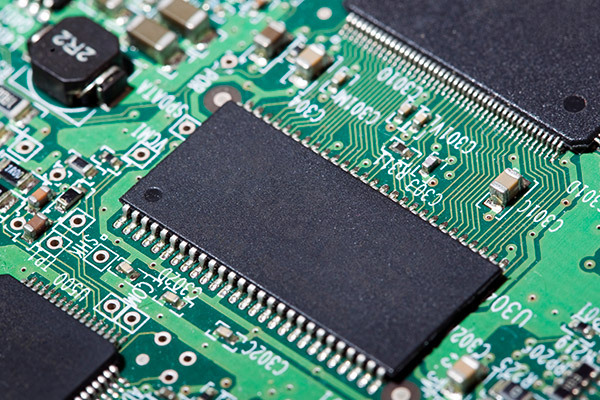

In the world of advanced electronics, maintaining cleanliness and performance is paramount. Our range of specialized cleaning chemicals is designed to meet the stringent requirements of various electronic components and systems, ensuring optimal functionality and longevity.

Conformal Coating Removal

Conformal coatings protect electronic circuits from harsh environmental conditions. However, when repairs or modifications are needed, these coatings must be carefully removed without damaging the underlying components.

Our conformal coating removal chemicals efficiently dissolve coatings while preserving the integrity of the delicate electronic parts. They are safe to use on various types of coatings, including acrylic, silicone, and urethane, making the removal process seamless and effective.

Hard Disk Drive Cleaning

Hard disk drives (HDDs) are critical for data storage and require meticulous cleaning to prevent data loss and hardware failure. Contaminants can affect the read/write heads and other sensitive components.

Our HDD cleaning chemicals are formulated to eliminate dust, grease, and other contaminants without leaving residues. They ensure that the HDDs operate smoothly and extend their lifespan by maintaining a pristine environment within the drive.

Die Cast Aluminum Housing Cleaning

Die cast aluminum housings are widely used in electronic devices for their durability and heat dissipation properties. Proper cleaning is essential to maintain these benefits and prevent corrosion and electrical faults.

Our cleaning agents for die cast aluminum housings remove oils, oxides, and other impurities. They are designed to be gentle on the metal while providing a thorough clean, ensuring the housings maintain their structural and thermal performance.

Printed Circuit Board (PCB) Cleaning

PCBs are the backbone of electronic devices, and even minor contaminants can cause significant issues. Cleaning PCBs requires chemicals that can remove flux residues, dust, and other contaminants without harming the board or its components.

Our PCB cleaning solutions are precision-formulated to clean effectively and safely. They help in maintaining the conductivity and reliability of the circuits, supporting the optimal performance of electronic devices.

Reagent Chemicals

Reagent chemicals are essential in various electronic manufacturing and testing processes. They must be of high purity to ensure accurate results and maintain the quality of electronic components.

We offer a comprehensive range of reagent chemicals that meet industry standards for purity and consistency. Our products support a wide array of applications, from material testing to product development, ensuring precision and reliability in every step.

Semiconductor Cleaning

Semiconductors are the core of modern electronics, and their manufacturing process involves multiple stages where cleanliness is critical. Any contamination can lead to defects and reduce the efficiency of the semiconductor devices.

Our semiconductor cleaning chemicals are engineered to remove microscopic particles, residues, and impurities. They ensure that the wafers and other semiconductor components remain free from contaminants, supporting high yields and superior device performance.

Solar Panel Cleaners

Solar panels are exposed to the elements, accumulating dirt, dust, and other residues that can hinder their efficiency. Regular cleaning is necessary to maintain their energy output and longevity.

Our solar panel cleaners are specially designed to remove tough contaminants without scratching or damaging the panels. They help in preserving the panels' transparency and efficiency, ensuring maximum energy production from your solar installations.

These specialized cleaning chemicals are designed to meet the highest standards of performance and safety, ensuring that your electronic components and systems remain clean, efficient, and reliable. Explore our range of products and find the perfect solution for your cleaning needs.

NuGenTec FluoSolv® formulated solvents have been used in many applications in the optics industry such as precision cleaning, deposition of anti-reflective & anti-static coatings and de-blocking. Many different types of pitch and wax are used for blocking during grinding and polishing of glass to make spherical and plano-optical components. FluoSolv CX® is a safe drop-in replacement for Asahiklin AK-225 solvent (Class II ODC) as well as nPB and other similar solvents.

FluoSolv® CX has shown excellent solvency when used in a vapor-degreaser for removal of pitch (e.g. Trinidad, Gugolz) and wax (e.g. Fixturewax, Hypo Wax etc.) due to its Kb value being high (95-100).

Higher soil loading allows the solvent bath to last longer before replacement, resulting in cost savings for new solvent and lower production downtime.

Field data for various waxes and pitch type is shown below for FluoSolv® CX

Features

To the best of our knowledge, this product is California Prop 65 compliant.

FluoSolv CX® Features

- Safe drop-in replacement for Asahiklin AK-225 solvent

- Safe drop-in replacement for nPB solvent

- FluoSolv CX® has shown excellent solvency when used in a vapor-degreaser for removal of pitch

- Higher soil loading allows the solvent bath to last longer before replacement

- Optics Pitch and Wax Removal

Soil Loading in FluoSolv CX @ bp 42°C

| wt % pitch or wax in solvent | |

| Paraffin Wax | 7 |

| Hypo Wax | 15 |

| Polish Pitch | 30 |

| Trinidad Pitch | 40 |

| Gugolz Pitch | 14 |

| Fixture Wax | 20 |

| Stacking Wax #4 | 16 |

Navigating the world of government contracts can open up a plethora of opportunities for businesses specializing in building materials, chemical products, and insulation. Working with government agencies, particularly through the General Services Administration (GSA), offers a steady and reliable market for high-quality products and services.

Building Materials

Government infrastructure projects require a wide array of building materials, ranging from structural steel to concrete, lumber, and finishing products. These materials must meet stringent standards to ensure durability, safety, and compliance with federal regulations.

Supplying building materials for government projects can lead to substantial and consistent business. The GSA often seeks suppliers who can provide high-quality, sustainable, and cost-effective materials for various federal, state, and local construction projects. This includes everything from new building constructions to renovations and maintenance of existing structures.

Chemical Products

Chemical products play a crucial role in numerous government operations, including cleaning, maintenance, and manufacturing processes. These products must adhere to strict environmental and safety standards to protect workers and the environment.

Government contracts for chemical products cover a broad spectrum, including industrial cleaners, coatings, adhesives, and specialized chemicals for scientific research. Businesses that can demonstrate compliance with federal regulations, such as those set by the Environmental Protection Agency (EPA), are well-positioned to secure contracts through the GSA.

Government Agencies (GSA)

The General Services Administration (GSA) is a key player in the federal procurement process, managing billions of dollars in contracts annually. The GSA’s mission is to deliver value and savings in real estate, acquisition, technology, and other mission-support services across the federal government.

Registering with the GSA as an approved vendor can significantly streamline the process of obtaining government contracts. The GSA schedules program, in particular, offers a simplified path for businesses to provide products and services to federal agencies. This program covers a wide range of categories, including building materials, chemical products, and insulation, among others.

Insulation

Insulation is critical for energy efficiency and environmental control in government buildings, military installations, and other public infrastructure. High-performance insulation materials can lead to significant energy savings and improved occupant comfort.

The demand for advanced insulation products is growing as government agencies seek to meet energy efficiency goals and reduce operational costs. Contracts for insulation materials and services are available for new construction projects as well as upgrades to existing facilities. Suppliers that offer innovative, sustainable, and cost-effective insulation solutions are in high demand.

By understanding the requirements and opportunities within government contracts, businesses specializing in building materials, chemical products, and insulation can secure valuable partnerships with government agencies like the GSA. This not only provides a stable revenue stream but also contributes to the development and maintenance of essential public infrastructure.

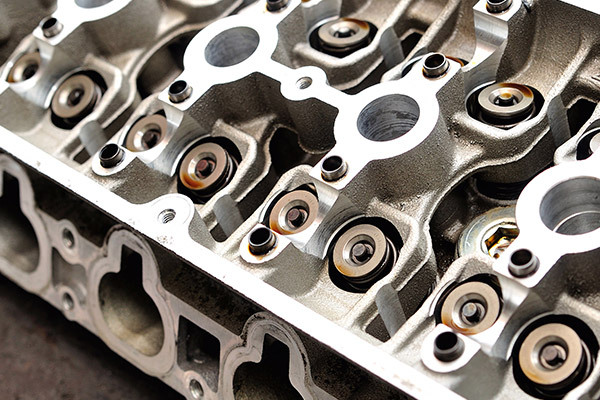

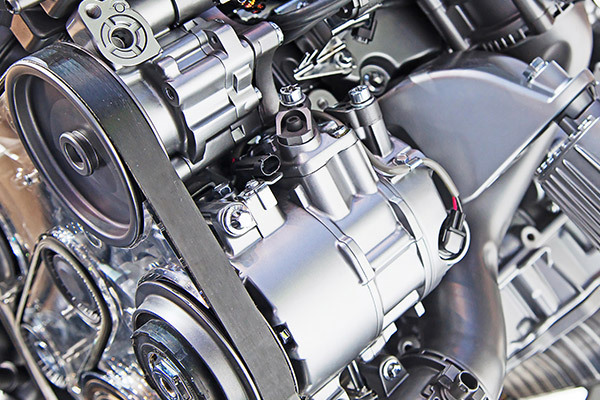

At the heart of high-quality metal fabrication lies the art and science of metal finishing. Our comprehensive range of metal finishing solutions ensures that your metal components not only meet but exceed industry standards for performance, durability, and aesthetics.

Metal Cleaning & Degreasing

Effective metal cleaning and degreasing are critical first steps in the metal finishing process. Removing oils, dirt, and other contaminants ensures that subsequent treatments, such as plating, coating, or welding, adhere properly and perform optimally.

Our metal cleaning and degreasing products are designed to tackle the toughest contaminants without damaging the underlying metal. We offer a variety of formulations suitable for different metals and applications, ensuring that your components are thoroughly clean and ready for further processing. Whether you need aqueous-based cleaners, solvent-based degreasers, or specialized solutions for sensitive materials, we have the right product to meet your needs.

Metal Working Lubricants

Lubricants play a crucial role in metalworking processes such as cutting, forming, and machining. They reduce friction, minimize wear, and help maintain the integrity of the metal, ensuring precision and extending the life of your tools and machinery.

Our range of metalworking lubricants includes cutting fluids, drawing compounds, and forming lubricants, all formulated to provide superior performance under demanding conditions. Our lubricants help improve the efficiency of your operations, reduce downtime, and ensure a high-quality finish on your metal parts. We offer solutions tailored to various metals and processes, ensuring that you can find the perfect lubricant for your specific application.

Electropolishing

Electropolishing is a precision process that enhances the surface finish of metal parts by removing a thin layer of material. This process results in a smooth, reflective surface that improves corrosion resistance, reduces friction, and enhances the overall appearance of the metal.

Our electropolishing services deliver exceptional results for a wide range of metals, including stainless steel, aluminum, and nickel alloys. By using state-of-the-art equipment and carefully controlled processes, we achieve a mirror-like finish that meets the highest industry standards. Electropolishing is ideal for components used in medical devices, food processing equipment, aerospace, and other applications where surface quality is paramount.

Enhance your metal components with our comprehensive metal finishing solutions. Contact us today to learn more about how we can help you achieve superior quality and performance in your metalworking projects.

Transform your spaces with our premium range of latex paints designed for interior use. Our selection of finishes, including Flat Finish, Eggshell Enamel, and Semi-Gloss Enamel, ensures that you find the perfect match for your aesthetic and functional needs.

Latex Paints Interior

Latex paints are a popular choice for interior applications due to their ease of use, quick drying times, and durability. Our high-quality latex paints provide excellent coverage and a smooth finish, making them ideal for various surfaces and rooms.

Advantages:

- Eco-Friendly: Low-VOC formulations for a healthier indoor environment.

- Durability: Resistant to peeling, fading, and staining.

- Easy Cleanup: Water-based formula for easy cleaning of tools and spills.

Flat Finish

Flat finish paints provide a smooth, non-reflective surface that is perfect for concealing imperfections on walls and ceilings. This finish is ideal for low-traffic areas and creates a sophisticated, velvety look.

Applications:

- Living Rooms: Achieve a cozy, understated elegance.

- Bedrooms: Create a calm and relaxing atmosphere.

- Ceilings: Minimize light reflection and hide surface flaws.

Features:

- Excellent Coverage: Hides imperfections with fewer coats.

- Smooth Appearance: Provides a seamless, uniform look.

- Easy Touch-Up: Blends effortlessly with existing paint.

Eggshell Enamel

Eggshell enamel paints offer a soft, low-sheen finish that adds a touch of elegance to your interiors. This finish is more durable than flat paint and is suitable for moderate-traffic areas, providing a delicate balance between aesthetics and functionality.

Applications:

- Dining Rooms: Enhance the ambiance with a subtle, refined sheen.

- Hallways: Durable enough to withstand light scuffs and marks.

- Family Rooms: Perfect for creating a warm, inviting space.

Features:

- Mild Sheen: Provides a sophisticated look with slight light reflectance.

- Washable: Easy to clean, maintaining its beauty over time.

- Versatile: Suitable for a variety of interior surfaces.

Semi-Gloss Enamel

Semi-gloss enamel paints deliver a radiant, highly durable finish that is perfect for areas requiring frequent cleaning. This finish is ideal for high-traffic and high-moisture environments, offering both beauty and resilience.

Applications:

- Kitchens: Resistant to stains and easy to wipe clean.

- Bathrooms: Withstands humidity and frequent cleaning.

- Trim and Doors: Highlights architectural details with a polished look.

Features:

- High Durability: Resistant to moisture, stains, and abrasion.

- Brilliant Shine: Reflects light, adding a bright, lively feel to spaces.

- Long-Lasting: Maintains its sheen and appearance over time.

Elevate your interiors with our premium latex paints. Whether you're looking for the elegant simplicity of a flat finish, the subtle sheen of eggshell enamel, or the durable brilliance of semi-gloss enamel, we have the perfect paint to transform your space. Contact us today to find out more about our products and how they can bring your vision to life.

NuGenTec exhibited at the SMTA - Surface Mount Technology Association - Expo Guadalajara, Mexico, November 2019

Product lines we will be showing

Silicone Oil Removers

- NuSolv™ SOR

- NuSolv™ SOR-C

- NuSolv™ SOR-A

- NuSolv SOR-Aerosol - No-Clean Flux Remover and Silicone Oil Cleaner

Conformal Coating Removers

No Clean Flux & Flux Removers

- NuSolv SOR-Aerosol - No-Clean Flux Remover and Silicone Oil Cleaner

- NuKlean® NCFR

- NuKlean® NCFR Plus

SMT Pallet Cleaners

- NuKlean® 239

- NuKlean® T389

Reflow Oven Cleaners

FluoSolv Non-flammable Solvents

Vapor Degreasing

- FluoSolv® AP - Boeing Approved BAC 5408

- FluoSolv® NC-786 (contains no chlorinated solvents)

- FluoSolv® CX

- FluoSolv® Ten-X

- FluoSolv® FR110 & CAS both Zero VOC and SCAQMD Approved

Aerosols

Features

To the best of our knowledge, this product is California Prop 65 compliant.